Westerntoolco.com is a proud distributor of RAPIDKUT products which include End Mills, Drills, Reamers Countersinks, Taps, Burrs, Boring, Dies, and Tool Bits.

Family owned and operated since 1940, RAPIDKUT was one of the first manufacturers of HSS End Mills. Beginning in Grand Rapids, Michigan, business swiftly grew, and through generations of constant improvement and manufacturing expertise has grown RAPIDKUT, into one of the utmost premier cutting tool manufacturers of our time. Obviously evolving into Carbide in the early 1980's RapidKut today offers one of the most comprehensive lines of HSS and Carbide Tooling available today.

Visit our online Catalog to purchase RAPIDKUT brand products or call 303-422-3413.

Western Tool Company is located in Arvada Colorado and specializes in Maintenance, Repair and Operations Products. We ship all over the United States.

Thursday, May 30, 2019

Sunday, May 26, 2019

DORIAN INDEXABLE TURNING TOOLS AT WESTERNTOOLCO.COM

Indexable Internal Turning Tools from Dorian

Western Tool has Dorian's complete line of turning tools and more. Visit our catalog for this featured product and much more:

FamilyName

Indexable S20U-MTUNL-4 Left Hand 1-1/4″ SH

•S-MTUN R/L Boring Bars

•Style UNegative 3° End Cutting Edge Anglefor negative triangle TNMG inserts

Thursday, May 9, 2019

HIGHLAND CARBIDE SINGLE POINT BRAZED TOOLING

Single-Point Brazed Tooling is a standard in the industry and with Highland Carbide. The product line has been with their company for 70-plus years and

continues to bring great results.

This ANSI brazed tooling group comes in a variety of sizes and shapes, allowing for broader applications. They are tough, with superior resistance to abrasion, wear, stress, and compression. Use them for right or left-hand cutting for turning or chamfering operations, for cut-off of tubing or bars, for threading, and for automotive and lathe operations.

To purchase Highland Carbide and many other brands and products, visit our online catalog

or call 303-422-3413.

Westerntoolco.com

This ANSI brazed tooling group comes in a variety of sizes and shapes, allowing for broader applications. They are tough, with superior resistance to abrasion, wear, stress, and compression. Use them for right or left-hand cutting for turning or chamfering operations, for cut-off of tubing or bars, for threading, and for automotive and lathe operations.

To purchase Highland Carbide and many other brands and products, visit our online catalog

or call 303-422-3413.

Westerntoolco.com

Sunday, May 5, 2019

HOW TO READ A VERNIER MICROMETER FROM MITITOYO

In this video Mitutoyo will show how to read a vernier micrometer. This is a great video if you want to learn how to read Mitutoyo micrometer for your millwork

projects. Mititoyo discusses how to read a vernier micrometer once you've measured your workpiece and lock the spindle using the spindle clamp. Watch the video for more. Visit Western Tool Company to order or call 303-422-3413

Monday, April 29, 2019

Round Tools From Radiac Abrasives from Westerntoolco.com

Radiac Round Tools

|

| Radiac Abrasives at Westerntoolco.com |

Wednesday, April 24, 2019

CGW ABRASIVES Z3 & TRIMMABLE FLAP DISCS

CGW's Z3® offers the

fastest material removal in the marketplace. All flap discs are made in

USA!

This product has polycotton backing which is the best backing material for a flap disc.

These discs provide easier edgework and enhanced strength.

To order CGW Abrasives, visit: Westerntoolco.com or call 303-422-3413

This product has polycotton backing which is the best backing material for a flap disc.

These discs provide easier edgework and enhanced strength.

To order CGW Abrasives, visit: Westerntoolco.com or call 303-422-3413

Monday, April 22, 2019

AMADA TURRET PUNCH PRESS TOOLING AT WESTERNTOOLCO.COM

Amada Turret Punch Press Tooling

AMADA tooling products are designed to integrate

seamlessly with all AMADA machines. Our

tooling is subjected to exacting accuracy and endurance tests to guarantee peak performance. The knowledge that we have gained from extensive tooling experience has confirmed our conviction that the use of superior tooling ensures optimum production performance. AMADA’s goal is simple; to provide quality tooling that maximizes productivity and extends machine and tool life.

tooling is subjected to exacting accuracy and endurance tests to guarantee peak performance. The knowledge that we have gained from extensive tooling experience has confirmed our conviction that the use of superior tooling ensures optimum production performance. AMADA’s goal is simple; to provide quality tooling that maximizes productivity and extends machine and tool life.

|

| Amada Products at Westerntoolco.com |

Friday, April 19, 2019

HIGHLAND CARBIDE DRIVES CARBIDE TOOL SUCCESS

|

| Highland Carbide from Westerntoolco.com |

HIGHLAND CARBIDE SUCCESS STORY

One

success Highland Carbide recently made was to convert a brazed tool to a Toolholder

and indexable insert for a company that machines a high volume of forged

metal castings. Their customer called to review the tooling and

application. They discovered that the tool body could be improved with a

better design, and that they could drastically improve strength and tool

life by going with a heat treated Tool holder and a coated insert.

The

result was a win-win… higher production rates, with a lower overall

tooling cost and significantly less downtime. At Highland Carbide, significant improvements have come in designing custom

Toolholders for specific applications. They can improve geometries to

increase the strength and effectiveness of the tool, and pair it with

any insert on the market.

Wednesday, April 17, 2019

PFERD HAS A NEW LOOK!

Pferd offers "single-source"

solutions for hand finishing, grinding, cutting, and specialty applications.

Check out their new product labeling for abrasives. To purchase Pferd products, visit: Westerntoolco.com or call 303-422-3413.

Read more here

New wheel and box label designs, same quality PFERD product!

Check out their new product labeling for abrasives. To purchase Pferd products, visit: Westerntoolco.com or call 303-422-3413.

Read more here

New wheel and box label designs, same quality PFERD product!

Sunday, April 14, 2019

METAL CUTTING TOOLS, HOW ARE THEY USED IN INDUSTRY?

Metal Cutting Tools - The Different Industries Where They Are Applied

Guest Post By Richard C. Milton Metal cutting is not a simple job. Obviously, it cannot be done with bare hands. It is therefore necessary to seek help from equipment or machineries. In this regard, the industrial product known as metal cutting tools have been innovated. Now, they are applied in several industries.

Metal cutting is not a simple job. Obviously, it cannot be done with bare hands. It is therefore necessary to seek help from equipment or machineries. In this regard, the industrial product known as metal cutting tools have been innovated. Now, they are applied in several industries.There is a rigid process behind metal cutting. It follows a series of steps before the output may be obtained. It also involves several technologies to come up with the right cut on the metal. Depending

on the type of metal to be cut, several techniques are applied. Below are the different industries that benefit from metal cutting processes and tools.

Automotive industry

VISIT WESTERNTOOLCO.COM FOR OUR COMPLETE LINE OF CUTTING TOOLS

The automotive industry is filled with changes to construe with the times. Modern innovations have to be made in each part. Since vehicles like cars and trucks require a lot of cutting and various designs, metal cutting tools are relevant in the process. Stamping die manufacture is thereby needed to produce the essential parts of these vehicles.Aside from stamping die manufacture to form car parts, the automotive industry requires tools for transmission shafts and gears. Likewise, the tools are needed in engine milling blocks. Industries rendering these materials offer short lead time in order to meet the client's production needs.

Aerospace industry

Just like the automotive industry, aerospace relies upon the use of metal cutting equipment. Specifically, turbine disc, turbine casing and fan casing are produced through the use of these materials. For turbine disc, standard tools deliver the stable functions of the end product. As for proper operation of turbine casings, appropriate amount of milling is required to manufacture the component.

Milling industry

Milling productivity is made possible with the appropriate metal cutting tools on hand. With these types of equipment, lower production cost is attained while reduced inventories lead to savings. It also results to better utilization of the different machines in the industry.

For face milling, the tools work depending on the depth of the cut needed as well as the size and material of the component. It also relies on surface demands as well as the machine type used. With shoulder milling on the other hand, shoulder cutters are designed in order to suit any type of operations for the industry.

As for other tools in the milling industry, different requirements are made for profile milling and slot milling. On top of all things, the tools are geared to cut shapes even in the most complex forms.

Visit the Buy American Industrial Directory to find leading manufacturers of industrial equipment, machinery and supplies based in the U.S., Canada and Mexico offering a wide range of metal cutting tools and other products and solutions for the global industrial marketplace.

Article Source: http://EzineArticles.com/expert/Richard_C._Milton/324720

http://EzineArticles.com/?Metal-Cutting-Tools---The-Different-Industries-Where-They-Are-Applied&id=2455299

Thursday, April 11, 2019

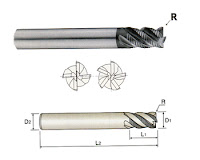

YG-1: X-SPEED, CARBIDE MULTI FLUTE STUB LENGTH FINE PITCH ROUGHING

YG-1: X-SPEED, CARBIDE MULTI FLUTE STUB LENGTH FINE PITCH ROUGHING FROM WESTERNTOOLCO.COM

To purchase YG-1 products, visit Westerntoolco.com- Featuring unique flute design for chip evacuation and vibration reduction

- Optimal roughing tooth profile to reduce cutting forces

- Special tool geometry for high feed rate and heavy cutting

- Strong end tooth design for plunge milling

- Custom engineered coating to allow long tool life and excellent chip evacuation

Monday, April 8, 2019

CHEMETALL, ENVIRONMENTALLY FRIENDLY WITHOUT PHOSPHATES

Metal meets organic: The new Gardo® Hybrid technology for phosphate-free cold forming operations

The Gardo Hybrid technology is the first ever cold forming process for steel without phosphates, based on a conversion coating. With this innovative technology Chemetall, the global leading surfacetreatment company, responds to the market requirement for an environmentally-sound cold forming technology, combined with a high forming performance.

The Gardo Hybrid technology replaces the zinc-phosphate layer by a phosphate-free metal-organic one. This innovative conversion layer provides the same excellent properties and behaviors like a traditional zinc-phosphate. However it fulfills more stringent safety and environmental requirements: the product does not contain any heavy metals and the formation of the metal-organic layer consumes less energy.

Gardo Hybrid can be easily integrated into current cold forming operations since no major modifications to the lubricant, treatment line or application process is needed. The reason for this is that the tribological system was not changed; it is still divided into two parts: the conversion layer providing the unique surface and the lubricant on top

Gardo® Hybrid advantages at a glance:

- Less energy due to lower treatment temperature

- Less consumption

- Reduced sludge formation

- No activation needed

- Free of heavy metals, except iron

- No major change in treatment lines required

- No additional equipment needed

- Safety, health and environmentally-friendly

Thursday, April 4, 2019

INGERSOLL SOLID CARBIDE END MILL FROM Westertoolco.com

Watch the Solid Carbide End Mill in Action from Ingersoll:

Tool - 3in1-Round Roughing End Mill w/ Variable Pitch & Chip Splitters

Operation - Profiling

Material - 4140

Diameter -- 0.625

SFM - 1250

RPM - 7640

IPM -- 443,260,434

APT -- 0.003

WOC -- Varied

DOC -- 0.050

Call 303-422-3413 to order or visit westerntoolco.com

Tool - 3in1-Round Roughing End Mill w/ Variable Pitch & Chip Splitters

Operation - Profiling

Material - 4140

Diameter -- 0.625

SFM - 1250

RPM - 7640

IPM -- 443,260,434

APT -- 0.003

WOC -- Varied

DOC -- 0.050

Call 303-422-3413 to order or visit westerntoolco.com

Sunday, March 31, 2019

SURFPREP, BRING THE FUN BACK INTO SANDING!

The SurfPrep Sanding System has “brought the fun” back into sanding.

When one thinks about sanding, they usually don’t think “fun”…sanding

isn’t fun; however, SurfPrep has reduced and eliminated what has always

been a sanding department’s most mundane, boring, time-consuming task.

Although sanding and preparing a surface is a critical step, doing so

with SurfPrep makes for a

The SurfPrep Sanding System has “brought the fun” back into sanding.

When one thinks about sanding, they usually don’t think “fun”…sanding

isn’t fun; however, SurfPrep has reduced and eliminated what has always

been a sanding department’s most mundane, boring, time-consuming task.

Although sanding and preparing a surface is a critical step, doing so

with SurfPrep makes for a better overall quality finish. SurfPrep has fine-tuned its variety of sanding systems by adding new products to the kits. During thousands of technical visits to woodworking manufacturers in North America, their team discovered areas in production that would benefit with a larger variety of foam abrasives and accessories. These products are minimizing physical effort and discomfort which maximizes efficiency in production lines from beginning to end; white wood to stain. Each kit comes with a SurfPrep Sander, 12’ Air Hose, Variety Packs of both Foam & Film as well as specialized accessories.

To purchase Surfprep products, visit our site and online catalog at Westerntoolco.com

Friday, March 29, 2019

PFERD TOUGH BURS FROM WESTERNTOOLCO.COM

For heavy-duty applications in shipyards, foundries and steel

construction, PFERD has developed two new special cut patterns for its

tungsten carbide burs.

The new 3R and 3RS cuts represent a new PFERD product line designed especially for tough operating conditions. These tungsten carbide burs are characterized by their exceptional impact resistance and performance. The new cuts are ideal for all uses involving high mechanical shock or impact loads. Susceptibility to tooth chipping/breakage, splintering and bur head cracking has been effectively minimized.

Even when milling at low RPM with an only moderately powerful machine, the occurrence of tooth failures is dramatically reduced. Westerntoolco.com is a proud Pferd distributor click here for more information.

excerpted from: Pferd

The new 3R and 3RS cuts represent a new PFERD product line designed especially for tough operating conditions. These tungsten carbide burs are characterized by their exceptional impact resistance and performance. The new cuts are ideal for all uses involving high mechanical shock or impact loads. Susceptibility to tooth chipping/breakage, splintering and bur head cracking has been effectively minimized.

Even when milling at low RPM with an only moderately powerful machine, the occurrence of tooth failures is dramatically reduced. Westerntoolco.com is a proud Pferd distributor click here for more information.

excerpted from: Pferd

Monday, March 25, 2019

DUST FREE SANDING: HERMES ABRASIVES AT WESTERNTOOLCO.COM

With its new MultiNet net abrasive, Hermes Schleifmittel is expanding its product range for dust-free sanding with a further high-performance variant. Together with the successful products MultiHole and FineNet, the industry has a tailor-made product set available from a one-stop shop for every sanding application involving painting. Dust-free sanding guarantees higher performance, best surface qualities and optimum conditions for people and the environment. The build-up of dust during sanding and the clogging of the abrasive resulting from this are a challenge for all applications in the paint shop. In particular, when sanding highly dusty materials such as fillers and primer, sanding dust has a negative effect on the sanding process in terms of quality and working environment. The same applies to the processing of aluminum and zinc-coated steel as well as composite materials such as CFRP and GFRP.

TO ORDER HERMES ABRASIVES, VISIT WESTERNTOOLCO.COM or call 303-422-3413

The new net abrasive MultiNet MN 921 VEL from Hermes Schleifmittel GmbH meets these challenges and, in addition to optimum conditions for people and materials, guarantees an efficient and therefore economical sanding process.

Product benefits you will appreciate

TO ORDER HERMES ABRASIVES, VISIT WESTERNTOOLCO.COM or call 303-422-3413

The new net abrasive MultiNet MN 921 VEL from Hermes Schleifmittel GmbH meets these challenges and, in addition to optimum conditions for people and materials, guarantees an efficient and therefore economical sanding process.

Product benefits you will appreciate

- Full-surface dust extraction through MultiNet net structure extends the service life of the abrasive tool

- The MultiNet net structure allows dust-free sanding and ensures optimal working conditions

- The dust-free and always visible workpiece surface enables a fast and exact control of the final results

- Extremely universally applicable – for manual sanding or on random orbital sanders as well as dry or wet

- High edge stability

- Easy disc change as no hole patterns need to be aligned

Friday, March 22, 2019

GEMINI AND SIRCA INDUSTRIAL COATINGS AT WESTERNTOOLCO.COM

Western Tool Company is Colorado's exclusive distributor of Gemini & Sirca Industrial Coatings including Paints, Lacquers, and Stains. Watch this video to learn more about Gemini and their high quality products. We distribute Gemini and Sirca throughout Colorado with delivery for some zip codes (pick-up is always available for zip codes where delivery is not available.)

Call 303-422-3413 or Visit our site for order information (Westerntoolco.com)

Call 303-422-3413 or Visit our site for order information (Westerntoolco.com)

Friday, February 15, 2019

Kyocera Cutting Tools Winter & Spring Promos

Kyocera Cutting Tools have been sold at Western Tool Companyfor many years. We partnered with Kyocera because of the high demand for their

products by our customers and the high quality of the inserts. Some of the

tooling offered by Kyocera includes Steel Toolholders for Milling, Turning,

Grooving, Threading and drilling metal.

They also make indexable metal cutting inserts that are made

of either Carbide, Cubic Boron Nitride, Ceramic, Cermet and even Polycrystaline

Diamond. Solid Carbide cutting tools for tight tolerance and micro-diameter

metal cutting applications are also products that can be purchased.

Kyocera launched dome new Metalworking products within the

past year/ Here is a video showcasing some of those tools from their YouTube

Channel.

Kyocera is offering quite a few promotional items this winter

through spring some of the products that Kyocera is promoting include:

MFH-Micro High Feed Mills, MFH-Mini High Feed Mills, MFH-RAPTOR High Feed Mills

and DRV Magic Drills.

Thanks for reading our blog! We would love to connect with you. We are active on many social media sites, be sure to connect with us on any of the sites below to keep in touch.

YouTube

Subscribe to:

Comments (Atom)